Research

My current research leverages a suite of multi-scale computational tools, ranging from electronic structure calculations to molecular dynamics, from high-throughput materials informatics to machine learning interatomic potentials, to study a variety of thermodynamic, kinetic, and mechanic phenomena generally observed in lithium-ion batteries and searching for new functional materials and design principles.

Data-driven interfacial engineering to design high-energy Li-ion batteries

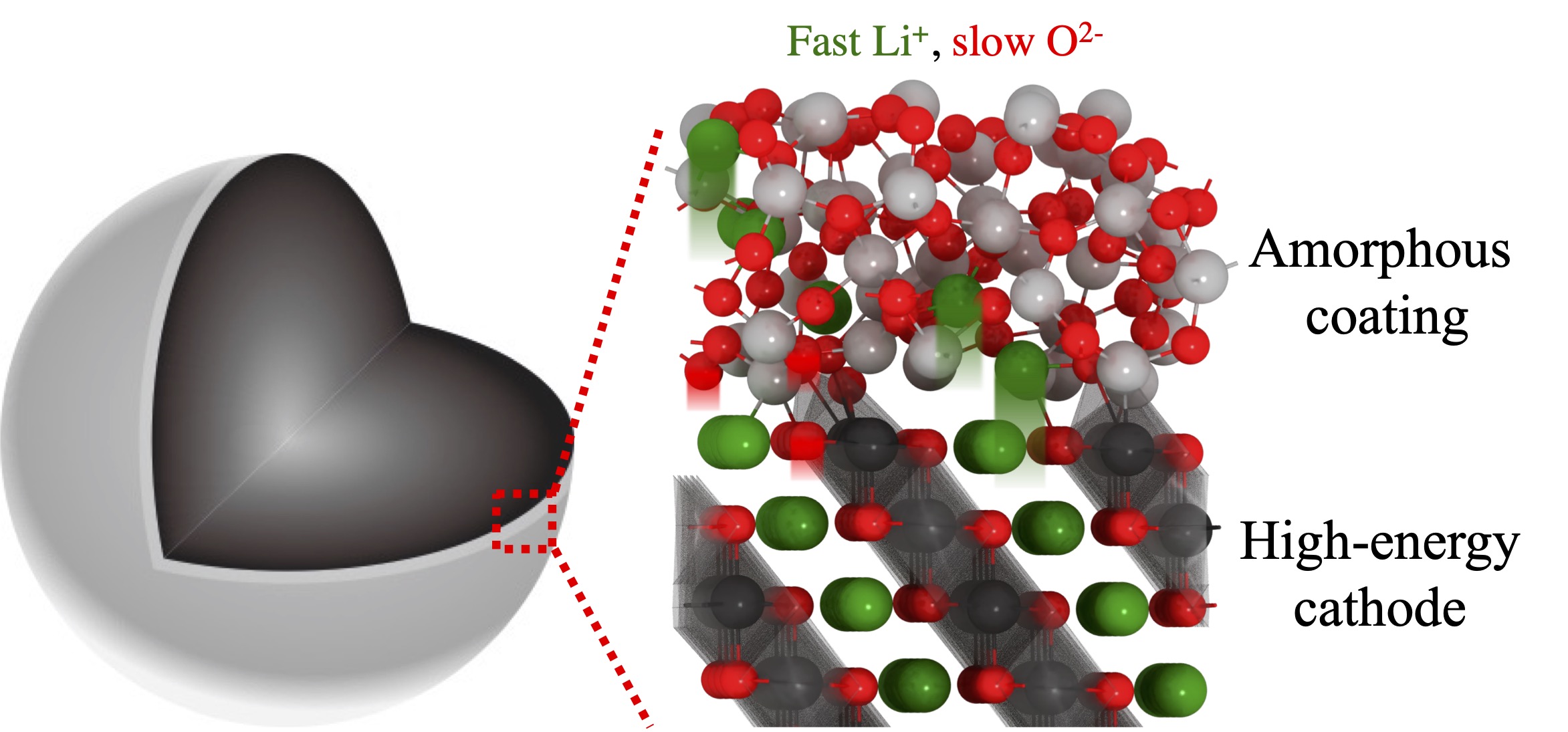

Future improvements in LIBs envision the use of lithium metal as the anode paired with high energy density cathode materials, such as high nickel layered oxides. However, these electrodes frequently experience surface instability with associated performance degradation under extended cycling. Therefore, it is critical to engineer the electrode surface to achieve high-energy LIBs with a safe and long-term cycling performance.

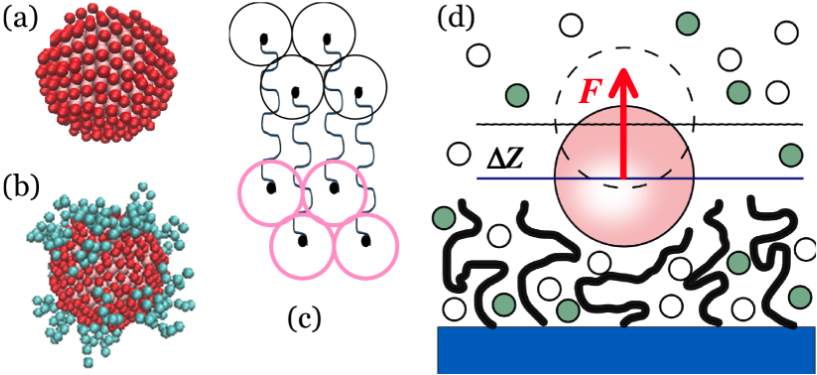

I use materials informatics, high-throughput simulations and machine learning to develop an interfacial engineering approach to stabilize the electrode surface. The screening criteria of selecting protective coatings include thermodynamic, electrochemical, chemical and mechanical stability, electronic conductivity and ionic diffusion of the electrode coatings. I have, for the first time, developed materials design principles governing amorphous cathode coating selections. Current, I am developing machine-learning interatomic potentials to study ionic diffusion and mechanical properties of electrode coatings.

J. Cheng, Kara D. Fong, Kristin A. Persson, “Materials Design Principles of Amorphous Cathode Coatings for Lithium-ion Battery Applications.” J. Mater. Chem. A, 10, 22245, (2022). [doi]

J. Cheng, E. Sivonxay, and K. Persson, “Evaluation of Amorphous Oxide Coatings for High-voltage Li-ion Battery Applications using a First-Principles Framework.” ACS Appl. Mater. Interfaces, 12, 31, 35748, (2020). [doi]

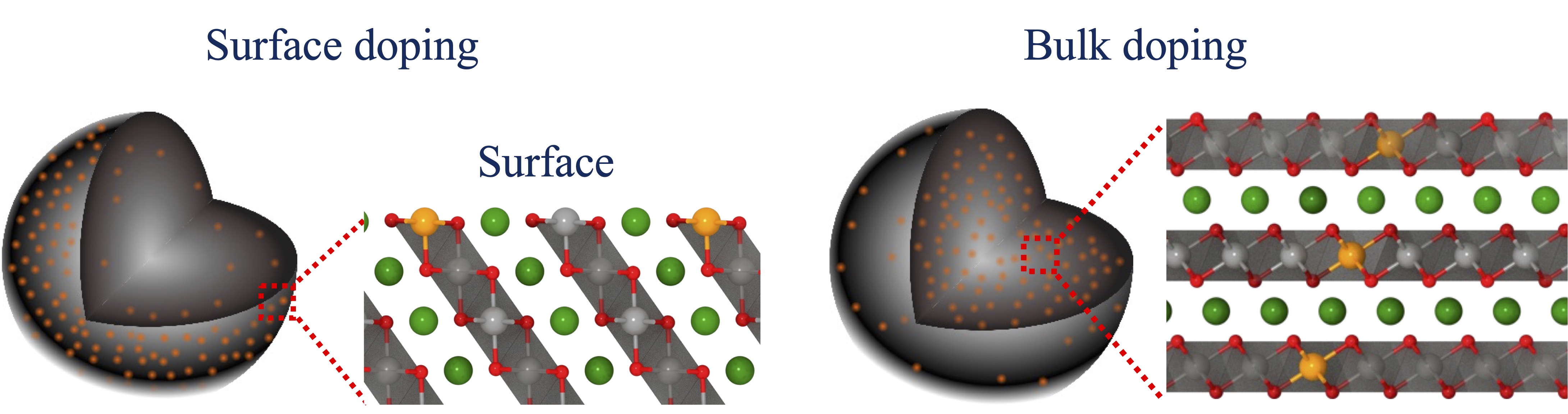

Theory-driven three-dimensional targeted doping to design next-generation cathode materials for Li-ion batteries

Apart from the surface instability, high energy-density cathodes also suffer from bulk instability which results from detrimental phase transformations and lattice contraction, especially at a high charge state. These two factors contribute to strain-induced structural damages in the cathode particles and associated performance degradation during cycling. Therefore, it is crucial to improve the phase stability of cathode bulk structures to achieve high energy density Li-ion batteries.

I am working on a theory-driven three-dimensional targeted doping approach to stabilize both cathode surface and bulk. My theoretical work in identifying effective surface dopants to mitigate the oxygen loss from the nickel-rich cathode surface guided our experimental collaborators to develop a novel Sb-doped LiNiO2 cathode with improved cycling performance. To predict bulk dopants that can mitigate phase transformations, I used a cluster-based Monte Carlo simulation approach to calculate temperature-composition phase diagrams. This work advances the understanding of phase transformations in Ni-rich layered cathodes Currently, I am developing materials design principles governing doping selections to achieve high energy-density LIBs with a stable and long-term cycling performance

J. Cheng, L. Mu, C. Wang, Z. Yang, H. Xin, F. Lin, and K. Persson, “Enhancing Surface Oxygen Retention through Theory-guided Doping Selection in Layered Ni-rich Cathodes for Next-generation Lithium-ion Batteries.” J. Mater. Chem. A, 8, 23293, (2020). [doi]

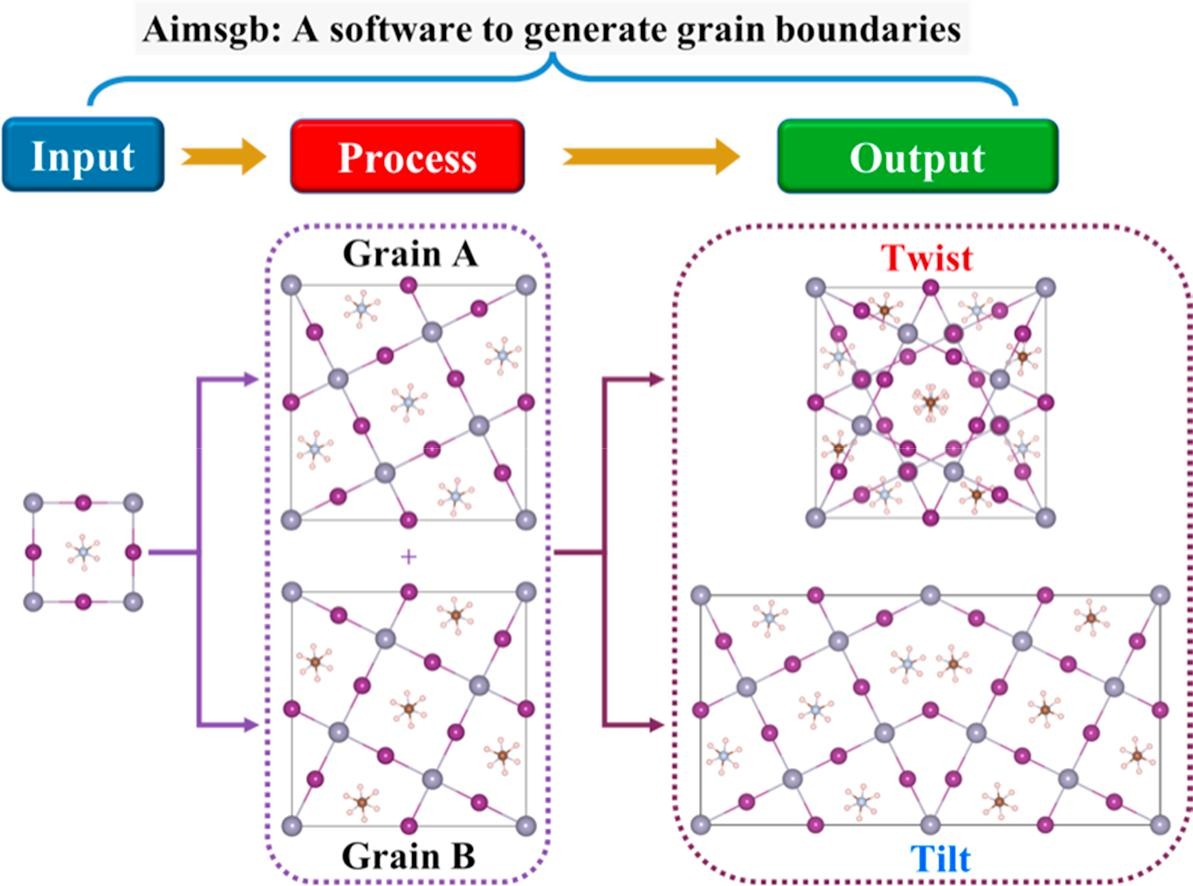

Aimsgb: generate periodic grain boundary structures

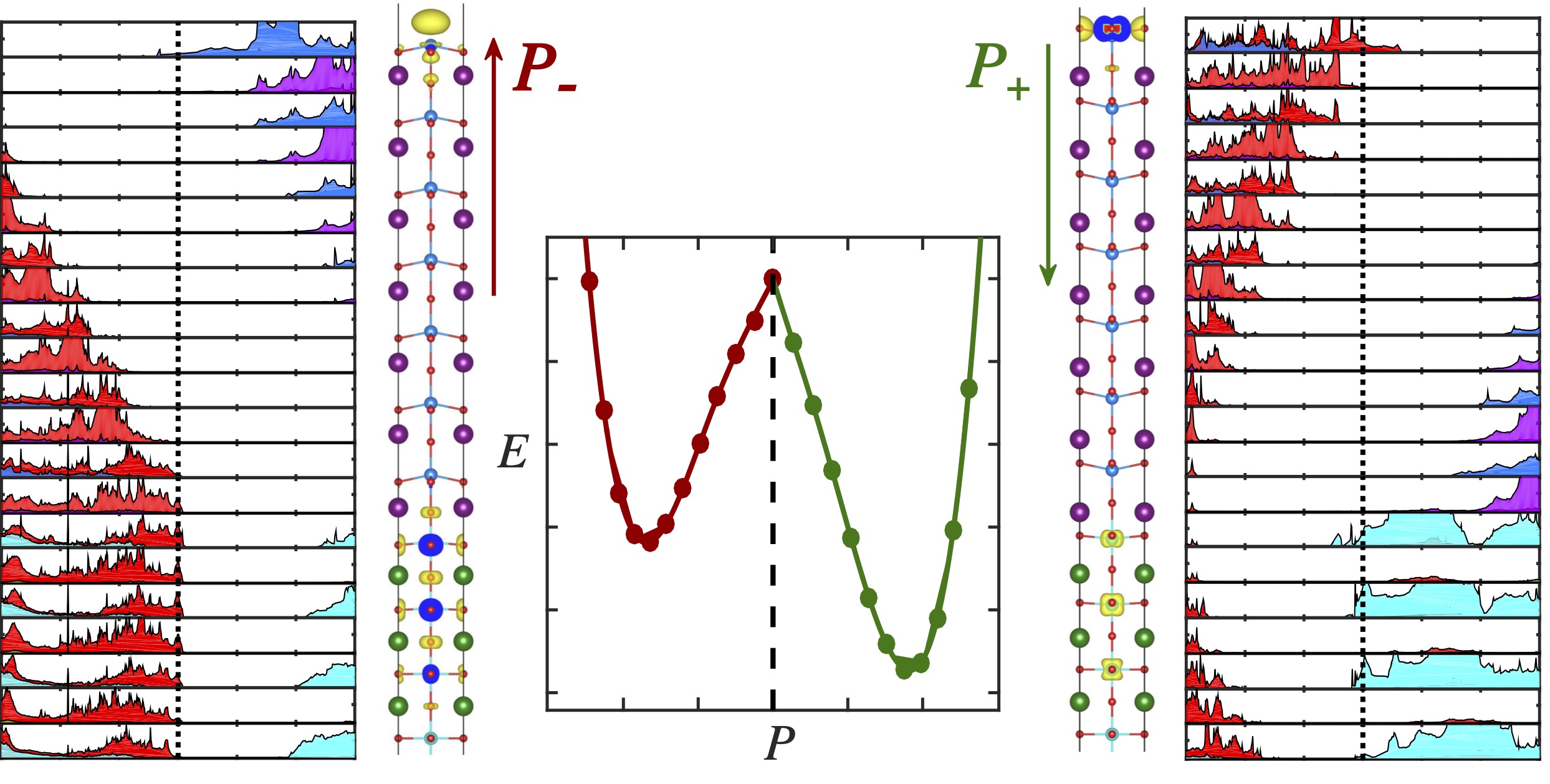

Two-dimensional electron gas in perovskite oxides heterointerfaces

Chromatographic separation of polymers and nanoparticles